Defence and safety

Component systems

Component systems for the security of Europe

Geopolitical challenges place great demands on the supply of critical goods in Europe.

Production lines must produce faster, run more stable for longer, and work more precisely.

Speed, traceability, and a robust system architecture are factors that contribute to our security –

especially when it is crucial that production chains function smoothly.

For almost four decades, we have been developing component systems for demanding industrial applications.

Today, we are increasingly involved in projects in the defence sector – as a European solution and service partner

for high-level component systems – working closely with OEMs and special machine manufacturers.

- Almost 40 years of automation

- Measurable quality

- Dual use

- Focus on cam technology

- High-level component systems

- Global footprint

Cams

Cam mechanisms for extreme demands

Our cam technology enables high-precision motion sequences that operate with extreme reliability even at high speeds.

High acceleration, short cycle times, and a reproducible process quality are its hallmarks – key requirements for applications in safety-critical environments.

With its own development, manufacturing, and system integration capabilities, TAKTOMAT is one of the world's

leading specialists in cam-controlled high-performance mechanics.

Contenu externe - Flux YouTube

Vous trouverez ici le contenu d'un fournisseur tiers, qui peut être affiché en un seul clic.

Par conséquent, les données personnelles peuvent être transmises au fournisseur tiers. Vous pouvez trouver plus d'informations dans notre politique de confidentialité.

Areas of expertise

Three areas of expertise

Whether high-performance components, targeted optimization, or engineering with partners – we develop automation solutions for manufacturing that deliver reliably. Especially where defence-related goods are produced under tight time, quality, and stability requirements.

High-speed component systems

Our high-level systems support high-speed production processes that meet demanding technical and documentary requirements.

- High speed

- Maximum load capacity

- High performance (OEE, cycle time, FPY)

- Reliability in operation

- Process chaining

- Modular design

Technology Consulting and optimization

We analyse systems, identify performance reserves, and increase output. Our validated components and KPI evidence (OEE, cycle time, FPY) help to increase performance and reduce risks.

- Identify performance potential

- KPI-based target values

- Prioritized measures and retrofit paths

- Reduced integration effort

Co-Engineering & Dual Use

Early co-engineering with partners enables flexible systems for safety-related applications.

The transfer of best practices from almost 40 years of experience creates dual-use added value –

technological synergies that increase performance, efficiency, and cost-effectiveness at the same time.

- Greater planning reliability

- Faster implementation

- Dual-use capability

- Know-how transfer

- Improved cost-effectiveness

High-Level

High-level components for high performance

High speed, precise movement, reliable continuous operation – TAKTOMAT systems work even under extreme conditions – with smooth motion profiles, high repeatability, and minimal maintenance requirements.

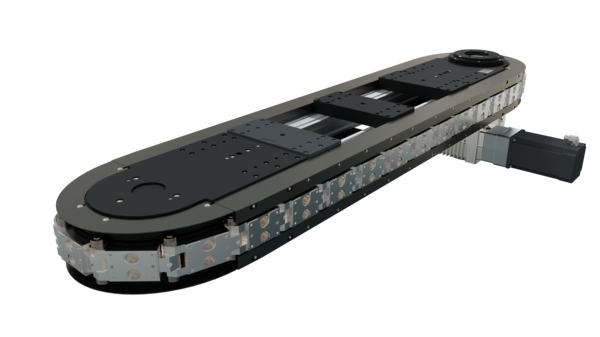

The linear transfer system LFA: High cycle times of up to 200 per minute with smooth and precise processes. The mechanics are robust and virtually maintenance-free.

It can be used flexibly in different installation positions - both horizontally and vertically. Its movement profile can be individually adapted to the respective customer requirements.

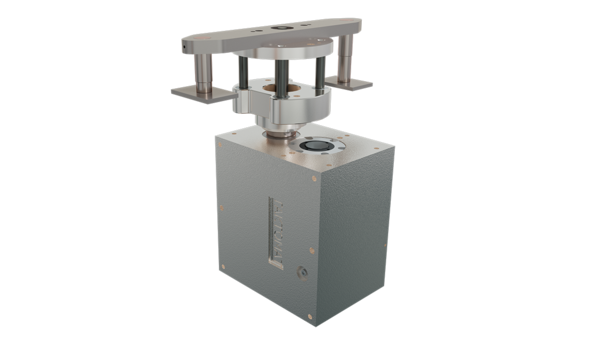

The pick & place system: Picks up components, moves them along a defined path, and reliably places them at the next station. It combines high cycle rates with precise handling, is compact and robust, and is virtually maintenance-free.

The customized design ensures that the module delivers stable, reproducible movement even in demanding processes.

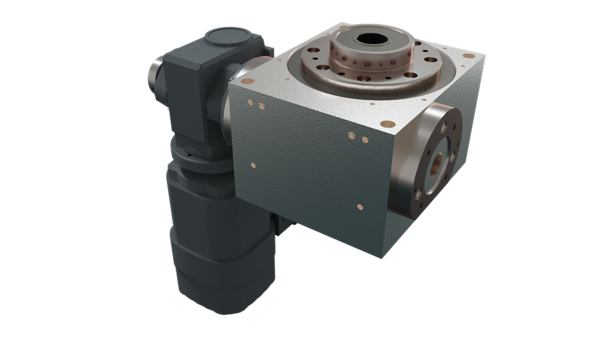

The rotary indexer RTX: Positions components precisely from station to station. Its strength lies in its high repeat accuracy, even under continuous load. The cycle rates are up to 150 cycles/minute.

The robust mechanics can be flexibly integrated into various systems and ensure precise, smooth positioning for complex processes.

Example

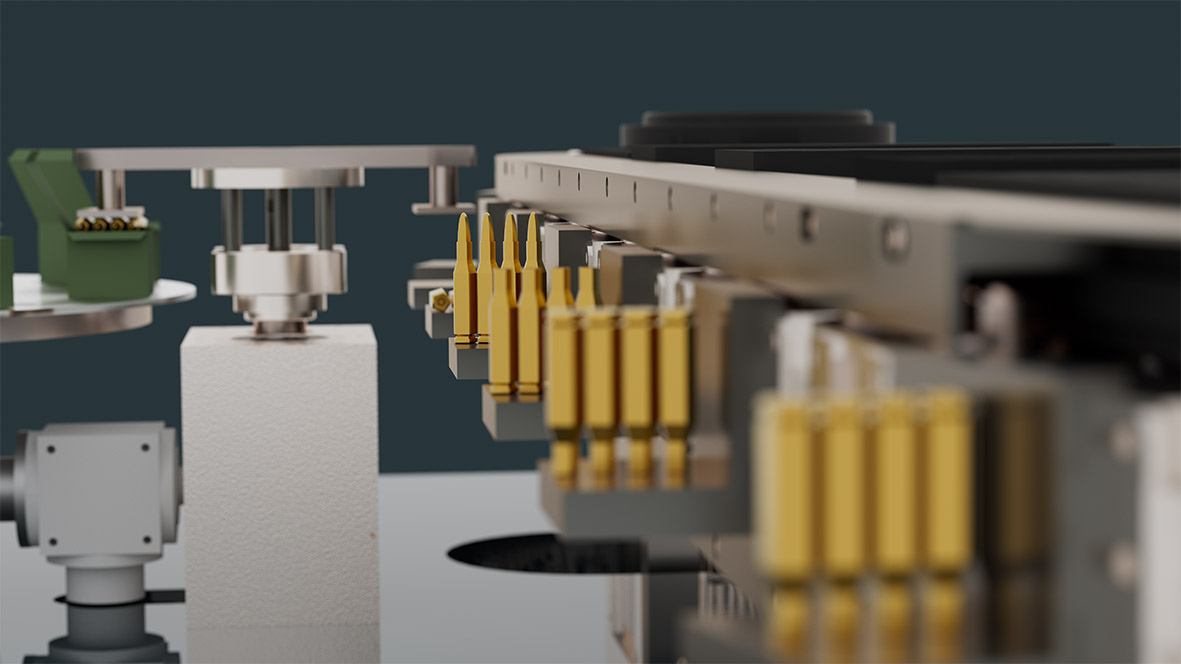

High-speed ammunition production

The video shows a high-precision production line for ammunition components.

A linear transfer system guides the components steadily through the stations, a rotary table positions them with precise timing, and pick-and-place modules take care of the precise handling. Harmonic motion profiles enable short cycle times, smooth processes, and a significant increase in line performance of up to 30 %.

Contenu externe - Flux YouTube

Vous trouverez ici le contenu d'un fournisseur tiers, qui peut être affiché en un seul clic.

Par conséquent, les données personnelles peuvent être transmises au fournisseur tiers. Vous pouvez trouver plus d'informations dans notre politique de confidentialité.